Atlas Copco, long committed to developing advanced process filtration solutions, has introduced a new generation of membrane filters designed to ensure high reliability, improved energy efficiency, and reduced water consumption across industrial production processes. According to the company, the new cartridges provide effective sterilization and bacterial load control, enabling greater productivity, improved uptime, and optimized system performance.

Membrane filtration is a separation process that removes suspended solids and biological or chemical contaminants, aiming to produce purified liquids. The membranes act as selective barriers, allowing only particles of specific sizes to pass through while retaining unwanted elements.

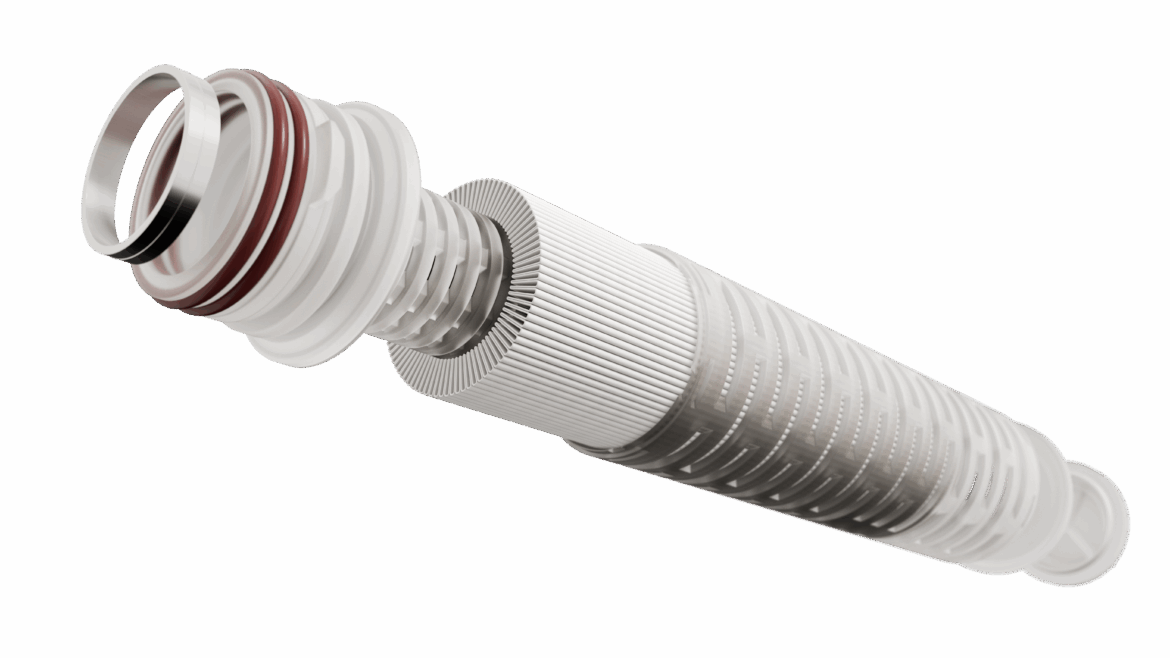

The new SME⁺ filter cartridge from Atlas Copco has been engineered to deliver safe, reliable, and efficient microbial load control and liquid sterilization, particularly in the food, chemical, and pharmaceutical industries. The filters use a modified polyethersulfone (PES) membrane, which is inherently hydrophilic (a property that allows materials to bond with water). Its key feature is an asymmetric porous structure, ensuring consistent porosity and contaminant retention throughout the filter’s service life, with no leaching or release of particles.

The SME⁺ series incorporates upstream and downstream polyester layers to improve liquid flow and reduce surface exposure to water compared to previous models. This results in lower pressure drop, greater permeability, and notable environmental benefits: 21% energy savings, 70% less water usage during cleaning cycles, reduced downtime, and increased operational efficiency compared to earlier membrane filter ranges. Additionally, waste is minimized thanks to optimized packaging, with each filter individually sealed in 200µm thick high-density polyethylene bags.

Each cartridge is fully traceable, with the production lot number printed directly on the unit and linked to a certificate of conformity — a key requirement to ensure compliance with HACCP standards, the risk analysis and control system used in the food industry to ensure product safety throughout the production chain.

“All components comply with both EU and US regulations for food-contact materials, including Title 21 of the CFR (Code of Federal Regulations) and Regulation EC/1935/2004 and its amendments. The filter element is manufactured according to Good Manufacturing Practices (GMP) as defined in EC Regulation No. 2023/2006. It does not release filtering materials, does not shed fibers, and is thermally bonded without adhesives or chemical additives,” the company explained.

“With their wide chemical compatibility, SME⁺ filter cartridges are ideal for a broad range of applications,” added Andrea Moretti, Business Development Manager for Process Filtration at Atlas Copco Italy. “These include particle and microorganism retention in liquids, bacterial load control, and the sterilization of consumable liquids such as bottled water, beer, wine, spirits, fruit juices, soft drinks, and still beverages. Their bacterial retention capacity meets ASTM F838-05, the standard used to define the retention characteristics of membrane filters.”